From the ceiling fan spinning quietly above your head to the engine roaring under the hood of your car, one technology powers them all: the motor. These mechanical marvels sit at the heart of countless devices, driving everything from household appliances to industrial machines. Understanding how motors work, the types available, and their construction not only empowers you as a technician or engineer but also deepens your appreciation for the devices you use daily. In this comprehensive guide, we’ll dive into the types of motors, their inner construction, and how they operate—breaking down complex ideas into simple, digestible insights that will stay with you long after reading. Whether you’re a student, professional, or just a curious mind, this article has something valuable for you.

Types of Motors

Motors come in various designs, each tailored for specific tasks. Depending on the power source, application, and performance requirements, engineers select the type that best fits the purpose.

AC Motors

AC motors run on alternating current, making them ideal for household and industrial use where AC power is standard.

Induction Motors

These are the most commonly used AC motors due to their ruggedness and simplicity. They don’t need brushes or commutators, which means lower maintenance. Induction motors consist of:

- Stator: The stationary part that produces a rotating magnetic field.

- Rotor: The rotating part that follows the magnetic field.

When AC power energizes the stator, a magnetic field rotates and induces current in the rotor, causing it to spin. Thanks to their robust design, induction motors power fans, pumps, and even escalators.

The above image shows the labeled components of an AC induction motor in an exploded view, illustrating how the parts fit together and function as a whole. At the center is the stator, which is the stationary part of the motor that produces a rotating magnetic field. The motor frame supports the stator and houses the motor components, while the wiring cover protects the electrical connections. The rotor, positioned inside the stator, is the rotating component that turns when the magnetic field interacts with it. Attached to the rotor are fan blades that help in cooling the motor during operation. At both ends of the motor are end bells, which provide structural support and enclose the ends of the motor. One of the end bells also contains a bearing, which allows the rotor shaft to spin smoothly with minimal friction. This assembly illustrates the fundamental construction of an AC induction motor, highlighting its essential mechanical and electrical parts.

Synchronous Motors

Unlike induction motors, synchronous motors run at a constant speed. They lock in with the supply frequency, which makes them perfect for precise timing applications like clocks, record players, and conveyor belts. Key components include:

- A stator similar to that in induction motors.

- A rotor wound with DC coils or fitted with permanent magnets.

Their precise speed control makes them suitable for processes where timing is crucial.

DC Motors

DC motors operate on direct current and excel in applications requiring speed control and torque.

Brushed DC Motors

These traditional motors use brushes to deliver current to the rotor windings through a commutator. Although they wear over time, they’re inexpensive and easy to control. You’ll find them in toys, automotive applications, and small tools.

Brush less DC Motors (BLDC)

Eliminating brushes improves durability and efficiency. BLDC motors use electronic controllers to switch current in the windings, offering quieter operation and longer life. These motors dominate in drones, electric cars, and computer fans due to their compact design and precise control.

Stepper Motors

Stepper motors divide a full rotation into multiple steps. Each step moves the shaft by a fixed angle, making them ideal for positioning applications like 3D printers, CNC machines, and robotics. They offer:

- Accurate control.

- Easy interfacing with micro controllers.

- High torque at low speeds.

However, stepper motors can lose steps under heavy loads unless feedback systems are in place.

Servo Motors

Servo motors specialize in precision. Controlled via feedback signals, they adjust position, speed, and torque dynamically. You’ll see them in robotics, camera systems, and automation lines. Their fast response and accuracy make them indispensable in complex machinery.

Motor Construction

To truly grasp how motors operate, you need to understand their construction. Although designs vary, most motors share common elements.

Stator

The stator remains fixed and generates the magnetic field that drives the rotor. In AC motors, it’s made of laminated iron cores with copper windings. In DC motors, it might use magnets or windings to create the required field.

Rotor

The rotor rotates within the stator’s magnetic field. Induction motors use squirrel cage rotors, while DC motors often have wound rotors connected to a commutator. For BLDC motors, permanent magnets are mounted directly on the rotor.

Bearings

Bearings support the rotor shaft and reduce friction. Without them, the rotor would quickly seize up. Proper lubrication and material choice extend motor life significantly.

Commutator and Brushes

In brushed DC motors, the commutator and brushes ensure that current flows correctly into the rotor windings, switching polarity as the motor turns. This mechanical switching is what keeps the rotor spinning in the same direction.

Cooling System

Larger motors generate substantial heat. Cooling fans, vents, and even liquid cooling systems help dissipate this heat to prevent damage. Temperature management plays a vital role in performance and longevity.

How Motors Work

Despite their varying designs, most motors rely on electromagnetic principles to function.

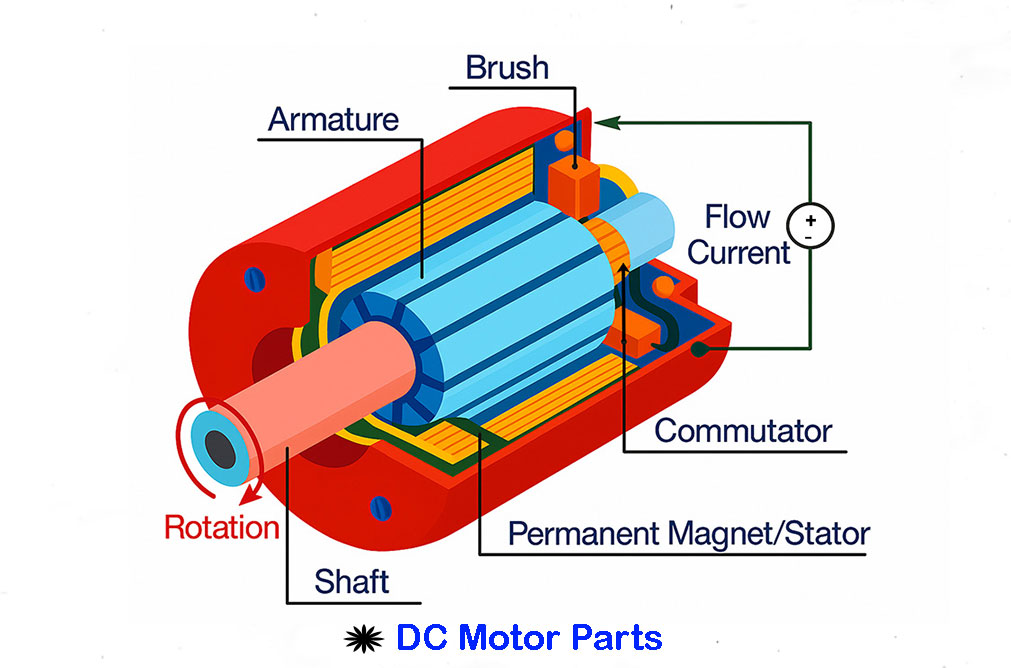

This above image illustrates the basic working of a DC motor. When electric current flows from the power source, it travels through the brushes into the commutator, which is a rotating split ring that ensures the direction of current in the armature coil changes every half turn. The current then flows through the armature (the rectangular loop of wire) positioned between the north and south poles of a magnet, creating a magnetic field perpendicular to the one from the permanent magnets. According to Fleming’s Left-Hand Rule, this interaction between the magnetic fields produces forces on the two sides of the armature: one side experiences an upward force and the other a downward force. This creates torque, causing the armature to rotate. The continuous switching of current direction by the commutator keeps the armature spinning in one direction, completing the motor’s function of converting electrical energy into mechanical rotation.

Electromagnetic Induction

The core idea behind motor operation is that a current-carrying conductor placed in a magnetic field experiences a force. In practical terms:

- The stator generates a magnetic field.

- Current flows through the rotor (or it has magnets).

- The magnetic interaction causes rotation.

This fundamental principle, first discovered by Michael Faraday, underpins nearly every motor design in use today.

Commutation

To maintain continuous rotation, motors must switch the direction of current periodically. In brushed motors, the commutator performs this function mechanically. In brushless motors, an electronic controller takes over, precisely timing the switching for smooth operation.

Torque and Speed Control

Motor performance depends on how torque and speed interact. Higher torque means more force, while speed refers to how fast the motor rotates. Engineers often trade off one for the other depending on application needs.

- High torque: Ideal for lifting, pressing, and heavy loads.

- High speed: Suited for fans, drills, and spinning applications.

In advanced motors, electronic controllers adjust voltage and frequency to achieve the desired balance.

Applications of Motors

Motors power our world in ways both visible and hidden. Their uses span across industries and devices, and knowing where they shine helps in choosing the right type for the job.

Household Applications

- Refrigerators and air conditioners use compressors driven by induction motors.

- Washing machines employ motors for both drum rotation and water pumping.

- Vacuum cleaners utilize high-speed universal motors for suction.

Industrial Uses

- Conveyor systems depend on synchronous motors for consistent speed.

- CNC machines benefit from stepper or servo motors for accuracy.

- Pumps and compressors in factories often rely on large three-phase induction motors.

Automotive and Aerospace

- Electric vehicles leverage BLDC motors for efficiency and range.

- Servo motors adjust control surfaces in aircraft.

- Window regulators and wiper systems in cars use small DC motors.

Emerging Technologies

- Robotics uses a blend of stepper and servo motors for flexible motion.

- Medical devices depend on compact motors for reliability.

- Drones utilize brush less motors for thrust and maneuverability.

Motor Comparison Table

| Motor Type | Power Source | Key Features | Common Uses |

|---|---|---|---|

| Induction Motor | AC | Rugged, low maintenance | HVAC, industrial machinery |

| Synchronous Motor | AC | Constant speed, precise timing | Clocks, conveyors |

| Brushed DC Motor | DC | Simple, cost-effective | Toys, car windows |

| Brush less DC Motor | DC | Quiet, efficient | Drones, fans, EVs |

| Stepper Motor | DC | Step-based movement | 3D printers, automation |

| Servo Motor | AC/DC | Feedback-controlled accuracy | Robotics, CNCs |

Frequently Asked Questions

What’s the difference between AC and DC motors?

AC motors run on alternating current and often power appliances and industrial tools. DC motors use direct current and are common in battery-powered applications. The main difference lies in how they handle electricity and their control systems.

Which motor is best for speed control?

Brush less DC motors and servo motors offer excellent speed control due to their advanced electronic systems. Stepper motors also allow control, but they need external feedback for high precision.

Why do some motors overheat?

Overheating usually occurs due to poor ventilation, overload, or inadequate cooling systems. Always ensure proper load matching and routine maintenance.

Can motors run without maintenance?

Some motors, like induction types, require minimal upkeep. However, components like brushes and bearings eventually wear out and need attention to avoid breakdowns.

Are brush less motors better than brushed ones?

Generally, yes. Brush less motors last longer, run more quietly, and require less maintenance. However, brushed motors remain popular due to their simplicity and low cost.

eeecontent.com Electrical and Electronics Engineering Content.

eeecontent.com Electrical and Electronics Engineering Content.